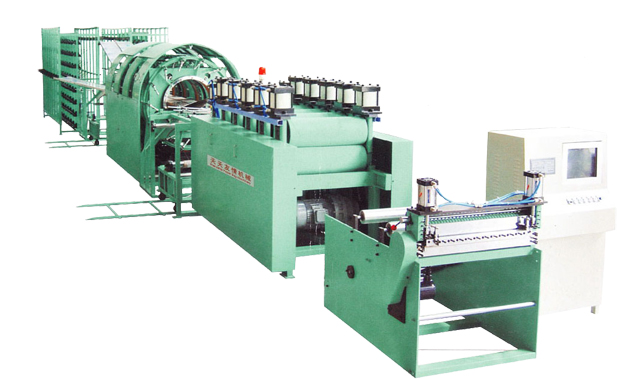

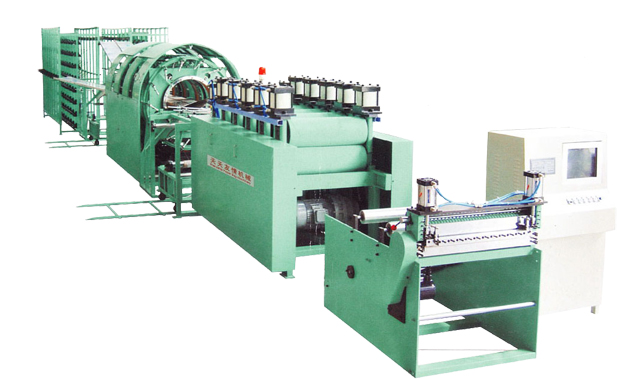

Introduction:

our factory developed this machine 8 years ago, on the basis of absorbing latest bag-making technology, we are continuing to improve its performance by integrating with latest technology from Europe.

A. Characteristics:

Simplicity:

Its design simplifies bag making steps, unlike PP woven bag production line which includes plastic yarn extruding machine, circular loom, film blowing machine, laminating machine, printing machine, etc; the bag made by this machine only one step: feeding of two layers of paper, yam and glue to the machine, then bag tube as its end product, then sewing by industry sewing machine.

Excellence:

The machine has excellent properties with quick bag-making speed in about 25 bags/min, two color printing, smooth running, and one machine with two purposes, i.e. then sewing its bottom. Its entire quality index reached GB9774-1996 standard, and the waste bags can also be recollected. Therefore, it is an ideal green product to protect environment.

Compactness:

Since the structure of this machine has the feature of compactness in reasonable, it has no special requirement for the factory building.

Energy-Saving:

This machine only needs three workers, 9 KW consumption per 1000 bags making.

Quick Learning:

Installation and training period: within 15 working days.

Low Noise & low Cost, no pollution both bag making and bag itself |